hardness test iso|types of hardness testing methods : dealer ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials . Resultado da Previsão do Tempo. Hoje, domingo. Várzea Paulista, SP. Sol com algumas nuvens. Chove rápido durante o dia e à noite. Manhã. Tarde. Noite. 29º .

{plog:ftitle_list}

Rocket Launch Melbet Casino Bonus. Get the Best Betting E.

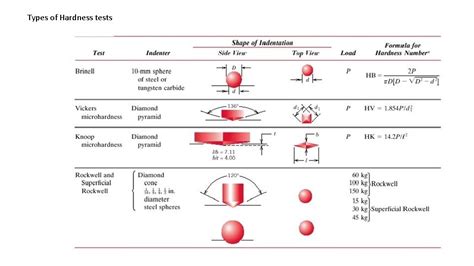

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop).This results in 30 different Rockwell scales standardized according to ISO 6508 and .Standardized optical hardness testing methods include the Brinell hardness .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials .

ISO 6508 consists of the following parts, under the general title Metallic materials — Rockwell hardness test: Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N, T) Part 2: Verification .tes Hardness responsible document is ISO/TC ng of metals, Subcommittee cancels and replaces the second edition (ISO 6506-1:2005), which has been technically ISO 6506 consists of the .

k-slump tester

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).

ISO 6507-1:2005 specifies the Vickers hardness test method for the three different ranges of test force for metallic materials. The Vickers hardness test is specified in ISO 6507-1:2005 for .This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic .This document was prepared by Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This fourth edition cancels and replaces the third .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .

Metallic materials — Brinell hardness test — Part 1: Test method 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g . ISO/TS 19278 standard enables precise hardness testing of plastics, even for thin or small specimens, using the DUH-210 tester. . The main test conditions of ISO/TS 19278 are shown in Table 1. Figure 1. Definition of .ISO 6508-2:2015(E) 4.3.2 The instrument or gauge blocks used to verify the depth-measuring system shall have a maximum expanded uncertainty of 0,000 3 mm when calculated with a 95 % confidence level. 4.3.3 Calibrate the testing machine’s depth measurement system at not less than four evenly spaced increments covering the full range of the normal working depth .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

ISO 6506-1:2014 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g. ISO 4498) and make reference to this International Standard.The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

Standardization in the field of indentation testing; specifying different indentation test methods, primarily for metals testing, at length scales ranging from nano to macro. Methods include the measurement of Brinell, Knoop, Leeb, Rockwell and Vickers hardness and also Instrumented Indentation Testing . zwickroell.com The result of a Brinell method depends on the tested material, force, ball size and dwell time. An inden-ISO 14577-1 can be used for the determination of hardness from smaller indentations.” A periodic verification method is specified for routine checking of the testing machine in service by the user. For specific materials and/or products, relevant International Standards exist.ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method; ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks; Only informative sections of standards are publicly available. To view the full content, you will need to purchase the standard by clicking on the .

ISO 3738-1, Hardmetals — Rockwell hardness test (scale A) — Part 1: Test method [2] ISO 4498, Sintered metal materials, excluding hardmetals — Determination of apparent hardness and microhardness [3] ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995) [4]The ISO 898-1, ISO 3506-1 and ASTM F606 standards describe tests on threaded fasteners (bolts, screws and studs) including steel screws and their mechanical and physical properties such as tensile strength, offset yield (minimum stress), elongation after fracture and hardness.. ISO 898-1 establishes the mechanical properties of fasteners made of carbon steel and alloy .Hardness testing assesses a material's ability to resist permanent deformation at its surface by applying pressure with a harder material. . ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell hardness tests, .

scuff-x reviews

Metallic materials — Rockwell hardness test — Part 1: Test method. Skip to main content. Applications . For specific materials and/or products, other specific International Standards apply (for instance, ISO 3738‑1 and ISO 4498). General information. Status : Withdrawn. Publication date : 2016-08. Stage: Withdrawal of International Standard

F ≥ 49,03 ≥HV 5 Vickers hardness test 1,961 ≤ F < 49,03 HV 0,2 to

However, the principles may be applied to Brinell hardness testing (with appropriate testing loads of HB 2,5/15,625. or HB 1/2,5) in accordance with ISO 6506-1 and micro hardness testing in accordance with ISO 6507-1 and. ISO 9015-2. NOTE Testing should be carried out to ensure that the highest and the lowest level of hardness of both parent .Rockwell hardness test metals; . (HR) kemudian dapat dihitung menurut rumus yang ditentukan dalam standar ISO 6508 dengan mengacu pada skala Rockwell yang diterapkan. Prosedur uji Rockwell Lekukan uji harus diatur sedemikian .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

no scuff

testing machines ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method ISO 6507-3, Metallic materials — Vickers hardness test — Part 3: Calibration of reference blocks . Before a Vickers hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up in accordance with the .force of (7,35 ± 0,15) N on the surface. The hardness of the pencil lead is increased in steps until the surface of the coating is marked by visible defects. The test result is the highest hardness at which no marking occurs. 5 Apparatus 5.1 Test instrument, consisting of a metal block fitted with two wheels, one on each side, as shown in .Metallic materials — Vickers hardness test — Part 1: Test method. Skip to main content. Applications; OBP; English. . ISO 6507-1:2018 Metallic materials — Vickers hardness test Part 1: Test method. Withdrawn (Edition 4, 2018) New .

ISO 9015-2:2016 specifies microhardness testing on transverse sections of welded joints of metallic materials with high hardness gradients. It covers Vickers hardness tests in accordance with ISO 6507‑1, normally with test loads of 0,98 N to less than 49 N (HV 0,1 to less than HV 5).

The Leeb hardness test is a dynamic test method and has the following characteristics:. It is one of the standardized methods (ISO 16859, ASTM A956).Depending on the method, the impact velocity is between 1.4-3.0 m/s. It is a rebound test method, which means that in order to determine the hardness value of a test piece, the velocity of an impactor is measured before .Rockwell hardness test ISO 2039-2, ASTM D785. ISO 2039-2 and ASTM D785 define various Rockwell hardness scales for plastics testing. In contrast to ball indention hardness, in which the indention depth is measured under load, with the Rockwell method, the indention depth is measured at a defined preload. There are a variety of indenters .ISO 6508-2, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters ISO 6508-3, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminology .ISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two

This document was prepared by Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This second edition cancels and replaces the first edition (ISO 6507-4:2005), which has been technically revised. A list of all parts in the ISO 6507 series can be found on the ISO website.

types of hardness tests

4 de set. de 2019 · Acumin Variable Concept Fonts Free Downloads. Download Formats. ttf web svg eot woff woff2 otf pfa bin pt3 ps cff t42 t11 dfont none. download. Version : 1.020;hotconv 1.0.108;makeotfexe .

hardness test iso|types of hardness testing methods